Situation: New

Warranty: 1.5 many years

Relevant Industries: mining market

Weight (KG): 1000

Video outgoing-inspection: Offered

Equipment Take a look at Report: Provided

Marketing and advertising Sort: Common Item

Guarantee of main factors: 3 years

Main Parts: Engine, Bearing

Regular or Nonstandard: Standard

Structure: Piston Cylinder

Energy: Hydraulic

Body Materials: Stainless Steel/Carbon metal

Product identify: Mini Excavator Hydraulic Cylinder Excavating Boom Arm Bucket Cylinder

Bore Size: 20-1000mm

Application: Truck

Functioning Strain: 20Mpa/30Mpa

Materials: ST52/CK45/SAE4140/SS304/SS316

Colour: at your proposal

Brand: ANBAO Group

Warmth Treatment: Quenching

Provider: OEM&ODM

Package deal: export regular packing

Packaging Specifics: export normal packing

Port: ZheJiang

Anbao Team Mini Excavator Hydraulic Cylinder Excavating Boom Arm Bucket Cylinder

A lot more than twenty a long time of planning and production cylinders

Specialize in tremendous large long non-standard cylinder

Developing Capability: Bore dimension twenty-800mm Stroke up to 16000mm

The max. rated work force is 32MPa.

Sealing techniqueAll the hydraulic cylinders made by our firm undertake the seal ring items of Parker, Merkel and Busak+Shamban.

Piston rodThe piston rod is produced of large power carbon metal with precision grinding remedy. With the layout concept of bettering the rod strength and the substantial overall performance warmth therapy, tough chrome plating and CNC tumbling, the even veins and substantial diploma of end of the surface is certain, and it has excellent oil membrane at the surface, which improves the service life of the seal areas.

Xihu (West Lake) Dis. sleeve

The sleeve is manufactured of higher strength spheroidal graphite forged iron and high power steel below buffering inner bore copper welding therapy.

Cylinder blockThe cylinder block is made of higher strength carbon metal. The inside floor of the cylinder is designed with suitable strength, dimension, and thickness of cylinder body, and it has good degree of finish and rigidity beneath the tumbling therapy which minimizes the internal friction, CZPT Swing Generate Slewing Generate Planetary Gearbox Gfb17t2, Gfb17t3, Gfb26t2, Gfb36t3, Gfb40t2, Gfb50t2, Gfb50t3, Gfb60t2, Gfb6 improves the wear resistance and prolongs the service daily life.

Piston and piston sealsThe common piston is of a single-piece steel framework. The firm lock-up amongst the long screw thread and the metal ball is handy for the set up and it also ensures the dependable procedure under large velocity load. New design of screwing components drastically improved the cross segment in which the piston rod bears the axial load and increases the toughness of piston rod to the greatest.

BufferingThe buffering sleeve of the cylinder is produced o

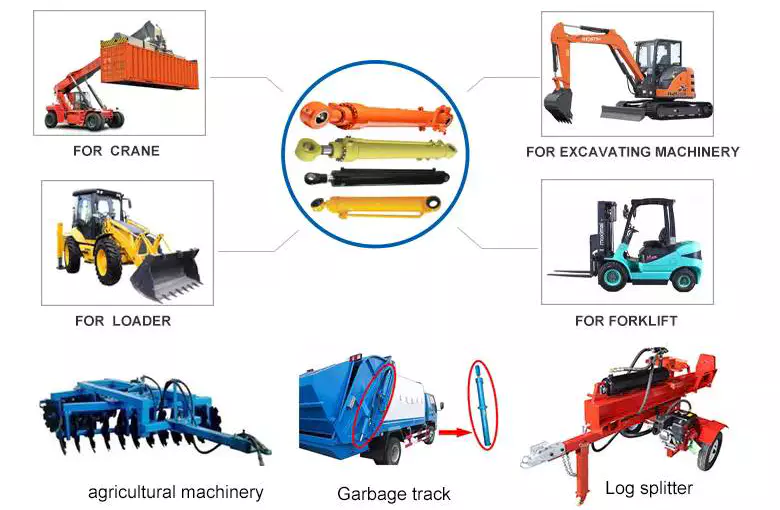

Software

Construction vehicle,excavator,crane,building machinery,shipbuilding,metallurgy sector,hydro energy task,agriculture equipment and many others.

We Also Source Honed Tube And Chrome Plated Bar FAQ:Q1: What are major variables that effect your value?

A: Value is effected by principal variables under:

one) Get amount: the greater quantity, the better price tag.

two) Uncooked steel price: if uncooked materials cost is secure, our cost is steady.

3) USD/RMB exchange price.

4) Dimensions: if it is regular dimensions, OEM jib small crane slewing ring bearing rotary help with SGS certificate cost is normal. If not, cost is based on measurement depth.

five) Duration: to make your expense down, we advise honed tubes length be unfixed 4 to 6 meter assortment. For chrome plated bars, we propose size be mounted 3 or 6 meter.

The proposed length is mainly determined by raw resources duration.

For illustration, if you need chrome plated bars duration 4.5 meter, cost is higher than the chromed bars with length 6 meter because the uncooked steel bar duration is 6 meter. If we create 4.5 meter, 1.5 meter length of the chrome plated rods will be squandered

Q2: What is the payment time period? How can we believe in you and make payment?

A: Standard payment is by T/T. Payment by LC can be negotiated.

We have exported to far more than thirty Countires and provided service for far more than a hundred clients. We are 9-12 months accredited CZPT supplier so much in Alibaba. So cooperating with us is very secure.

Q3: Can I have a going to to your manufacturing unit just before the buy?

A: Welcome to check out us. Pls make an appointment in advance. It is necessary to send browsing timetable and assembly details so that we can get ready and organize.

This fall: What is the deal? Can I print my emblem or manufacturer on the bundle?

A: The typical package deal is beneath:

Honed tubes bundle: oilded and capped on tub conclude. PE sheet bundles wrapped package or as for every request.

Chrome plated bars package deal: oiled and protected by hardboard sleeves, then in seaworty picket circumstance.

Hydaulic cylinder package: wrapped by PE film and packed in sturdy wooden situation.

Symbol or marking will be as for every customer’s ask for.

Software

Company Info

Packaging & Shipping

Benefits

Manufacturing unit Present

Buying Guide For Hydraulic Cylinders

Whether you are looking to replace a broken hydraulic cylinder or are interested in learning more about them, you will be glad to know that there are many options to choose from. The materials used to build cylinders, their stroke lengths and seals are just a few things to consider.

‘Parallel’ vs ‘Series’ cylinders

Choosing a hydraulic cylinder that is a good fit for your application is important. In general, there are two types of hydraulic cylinders: single-rod and tandem. In tandem cylinders, the two cylinders move in unison. This is the best way to transfer energy.

A welded body hydraulic cylinder is the most common type of hydraulic cylinder. It is used in construction equipment and other heavy industries. The cylinder body is welded in place and the base end is welded to it. It is normally rated for higher pressures.

A welded body hydraulic cylinder also has a built-in directional control valve. This valve works on both the inlet and the work ports. The oil from the pump goes through the control valves in series. This type of control valve usually has a small orifice drilled into it. It creates a pressure differential that forces the cylinders to work in unison.

Another type of hydraulic cylinder is the tie rod cylinder. It has a barrel and piston rod that is mounted on the bottom of the barrel. The piston rod operates both inside the barrel and out of the barrel.

There are many other types of hydraulic cylinders. Some of the more common include the plunger type, the tie rod type, and the single rod type. There are also many other types of cylinders, but they all have one thing in common: they use hydraulic fluid to power the piston.

The best hydraulic cylinder is one that can lift its weight. It is also important to select the best size for your application. The size of the cylinder depends on the load you intend to lift. If the loads are too large, you may have a difficult time maintaining synchronization. However, if the loads are not too heavy, you may be able to achieve the desired performance.

The hydraulic series relationship is a good place to start. If the loads are evenly distributed, the cylinders will work in unison. The flow control valves are a good way to keep cylinders in sync. A pilot-operated check valve is a good choice, as it will stop oil transfer when the mid-stroke is stopped.

Stroke lengths

Regardless of whether you’re buying a hydraulic cylinder for a small engine or a large excavator, the following guide can help you determine the optimal stroke length. The length is measured in inches. This is a standard measurement and is easy to obtain. The stroke is the distance covered by the rod and piston between the fully extended height and the fully retracted height of the cylinder.

The cylinder’s stroke can be measured in one of three ways. It can be based on the diameter of the rod, the diameter of the bore, or the difference between the maximum extended length and the minimum extended length. The cylinder’s stroke can range from a fraction of an inch to several feet. The stroke is a good indicator of the length of pull that can be exerted from the piston.

The largest part of the hydraulic cylinder is the rod. It is a round chrome-plated steel bar that performs the reciprocating motion. The diameter of the rod ranges from a few inches to twenty inches. It is referred to as the shiny part of the cylinder.

The retracted length is the distance between the centers of the mounting pins when the cylinder is closed. It is a standard measurement and can be measured with a tape measure. The retracted length is important for the proper functioning of the cylinder.

Using the retracted length, calculate the cylinder’s stroke. The stroke is the distance covered by the piston and rod between the fully extended height and the fully shortened height of the cylinder. This is the best indication of the length of pull that can be exerted.

The stroke is also the best indication of the length of lift that can be exerted from the piston. It can be measured using a caliper. The caliper can be used to measure the diameter of the rod and the thickness of the piston. It can also be used to calculate the difference between the maximum extended length and the maximum retracted length. This gives you the maximum length in the retracted position.

Materials used

Various materials are used in the manufacture of hydraulic cylinders. The materials have to be tough and durable enough to withstand the pressures of the hydraulic fluid. Besides, the materials must also be compatible with the hydraulic fluid. If the materials are not strong enough, the cylinder may not fully stroke.

Hydraulic cylinders are made of steel and other durable materials. They can be used in a variety of applications. They are used in manufacturing, construction, mining, and industrial technology. They can also be found in the aviation and aircraft industry. They have also been used in forestry.

Most hydraulic cylinders are made of 1018/1020 cold rolled steel. They are usually coated with Hard Chrome Plating to prevent corrosion. A variety of coatings are also available for cylinders.

In hydraulic systems, the fluid used is usually mineral oil or water glycol. Some cylinders also use fire resistant water glycol-based fluid. However, this type of fluid may still cause lubrication problems.

Another material used in hydraulic cylinders is stainless steel. These are generally inexpensive and easy to find. They are also environmentally friendly and work well with fuels and solvents. They are also durable in acidic environments.

Composite materials have also been used in the aerospace industry for years. They have also been used in high pressure vessels for CNG storage. They have a higher strength to weight ratio than steel. They have also been used in the automotive industry for many years.

The seal, piston, and steel ring work together to provide stability and control. They can also help ensure that the cylinder remains in place. These materials are also used for double-acting cylinders, which have ports on either side of the piston rod. The pressure on both sides of the piston rod helps control the movement of the cylinder.

Another type of cylinder is the tie rod style. This type of cylinder uses high-strength threaded steel tie rods to secure the cylinder. The tie rods stretch at high pressures, which allows the cylinder to function efficiently. The cylinders are commonly used in industrial factory applications.

Seals

Choosing the right seals for hydraulic cylinders is crucial to the functioning of a hydraulic system. These seals are designed to protect the internal components of the cylinder from contamination and leakage. They are used in various industries, including construction, agriculture and industrial plants.

Hydraulic cylinder seals come in a variety of designs. They are used in both static and dynamic applications. They are also subjected to high temperatures and high pressures. Therefore, they must be made of the right material to withstand the tough conditions. The seals must also be able to resist the change of hydraulic fluid.

Hydraulic cylinder seals are made from materials such as PTFE, polyurethane and rubber. These materials provide a durable seal for cylinders. They are also resistant to abrasion and tearing.

Seals for hydraulic cylinders are categorized into static and dynamic designs. Static seals are typically found in round cross-sections. They are used between the piston and the cylinder pipe. They are also known as gland seals. These seals are usually attached to the cylinder pipe with a threaded connection. The gland seal usually includes a wiper ring that keeps the interior of the cylinder clean and free from contamination.

Hydraulic cylinder seals also must be able to withstand high temperatures and high pressures. They are used in a variety of applications, including logging equipment. The main sealing material for hydraulic cylinders is polyurethane.

Seals for hydraulic cylinders can be made from thermoplastic or elastomeric polymers. These materials combine the strength of plastic with the flexibility of rubber. Thermoplastic elastomers also have better elasticity, enabling them to maintain constant pressure for longer periods of time.

In dynamic sealing systems, low friction coefficients are a basic requirement. This is due to the need for maximum tightness in dynamic conditions. Seal materials must also be capable of forming a tight seal against irregular metal surfaces.

The seal material must also be able to expand rapidly to follow dimensional changes. This is important for high-pressure cylinders, as they may undergo deformation. It is also important to use a material that can withstand corrosion.

editor by czh 2023-06-27