Regular or Nonstandard: Nonstandard

Composition: Piston Cylinder

Power: Hydraulic

Entire body Substance: Metal

Optimum Stroke: 2000mm

Shaft Diameter: 500mm max

Model Amount: HTR

Identify: Double Performing 3 ton hydraulic cylinder

Functioning Stress: 5800PSI max.

Bore Dia.: 2”2.5”3”3.5”4”5”

Warmth Therapy: Quenching

Sealing Elements: From Usa Herculesus

High quality Ensure: 1 year

Inspection: 100% inspection prior to shipping and delivery

Sample: For free

Certificate: ISO9001:2008

Packing: Wooden Box

Packaging Specifics: picket box/iron box

Port: HangZhou Port,China

Double Acting 3 ton hydraulic cylinder

Item Detail

| Title | Push pull double performing tie rod welded piston hydraulic cylinder |

| Working Strain | 5800PSI max. |

| Bore Dia. | 2”2.5”3”3.5”4”5” |

| Warmth Therapy | Quenching |

| Sealing Components | From United states of america Herculesus |

| High quality Guarantee | one calendar year |

| Inspection | 100% inspection before delivery |

| Sample | For totally free |

| Certificate | ISO9001:2008 |

| Packing | Wooden Box |

| Merchandise Search phrases | three ton hydraulic cylinder |

1. Seals kit: From Usa, resilient and tough-wearing with lengthy provider existence. 2. Warmth treatment: Quenching&Tempering which tends to make the piston rod tremendous substantial hardness. 3. Cleaning: Ultrasonic cleansing. 4. Cutting: Large precision offered by automatic roller reducing device. 5. Screening: Ultrasonic detector, spectrograph, China items Wholesale higher good quality assembly affordable stainless steel CZPT linear guideway rails for 3D Printer CMM, metallography, chrome thickness tester. 6. Edge: Easy composition & dependable work, effortless routine maintenance & Wholesale value miniature bearing 625zz 625rs 5165mm miniature slewing ring bearing varied connecting approaches. 7. Plan: Diverse manufacturing programs for diverse consumers. 8. MOQ: ten PCS of tie rod hydraulic cylinder 9. Direct time: ten~30 times depends on amount & regardless of whether tailored. ten. Warranty: Adjust a new 1 and we pay for the air freight in 3 many years guarantee time.

| Bore | B | C | D | E | F | G | H | I | J | K | M | N | Tube O.D. | Ports (NPT) |

| 2.00 (50.80) | 1.015 (twenty five.seventy eight) | two.a hundred twenty five (53.98) | 1.625 (41.28) | one.000 (twenty five.40) | one.000 (twenty five.40) | one.142 (29.01) | two.520 (sixty four.01) | two.835 (seventy two.01) | one.142 (29.01) | two.520 (64.01) | M10 | one-1/8 -12UNF | 2.375 (60.3) | 3/8 |

| 2.fifty (63.fifty) | 1.015 (twenty five.78) | two.one hundred twenty five (53.98) | 1.625 (41.28) | one.000 (twenty five.forty) | one.000 (25.forty) | 1.142 (29.01) | 2.520 (sixty four.01) | three.150 (80.01) | 1.142 (29.01) | 2.520 (64.01) | M10 | one-1/8 -12UNF | two.875 (seventy three.) | 3/eight |

| three.00 (seventy six.twenty) | one.015 (25.78) | two.125 (fifty three.98) | one.625 (forty one.28) | 1.125 (28.58) | one.000 (25.40) | 1.142 (29.01) | 2.600 (sixty six.04) | three.740 (ninety five.00) | one.142 (29.01) | two.520 (64.01) | M12 | one-1/4 -12UNF | 3.375 (85.7) | 1/2 |

| 3.50 (88.ninety) | one.015 (twenty five.seventy eight) | two.125 (fifty three.ninety eight) | 1.625 (41.28) | one.one hundred twenty five (28.fifty eight) | 1.125 (28.fifty eight) | one.142 (29.01) | 2.600 (sixty six.04) | 4.134 (105.00) | 1.142 (29.01) | 2.520 (64.01) | M12 | 1-1/4 -12UNF | 3.875 (ninety eight.4) | 1/2 |

| 4.00 (one hundred and one.60) | 1.015 (twenty five.seventy eight) | two.a hundred twenty five (fifty three.ninety eight) | one.625 (41.28) | one.125 (28.fifty eight) | one.125 (28.58) | one.142 (29.01) | two.600 (sixty six.04) | four.724 (119.99) | one.142 (29.01) | two.600 (64.01) | M12 | 1-1/4 -12UNF | 4.375 (111.1) | 1/2 |

| 5.00 (127.00) | one.015 (25.seventy eight) | two.125 (fifty three.98) | 1.625 (forty one.28) | one.250 (31.seventy five) | one.five hundred (38.10) | one.260 (3200) | 2.677 (68.00) | 6.000 (152.forty) | one.260 (32.00) | 3.five hundred (88.90) | M16M | one-1/4 -12UNF | five.453 (138.5) | 1/2 |

one.Descriptions of Chrome Plated Shaft

| Dimension | twenty five.4~100mm |

| Duration | .2m~2m |

| Materials | 45#DIN CK45/JIS 45C |

| Tolerance | ISO f7 |

| Chrome Thickness | twenty five~30micron |

| Hardness of The Chrome Layer | forty five~50HRC |

| Roughness | Ra0.4micron |

| Straightness | .2/1000mm |

| Produce Strength | ≥320Mpa |

| Tensile Energy | ≥580Mpa |

| Elongation | ≥15% |

| Offer Issue | 1.Challenging chrome plated |

| 2.Induction hardened | |

| three.Quenched& Skyplant Agriculture Drone Total Established Agriculture Spray Sprayer Tempered | |

| 4.Induction hardened with Q&T |

two.Chemical Composition

| Material | C% | Mn% | Si% | S% | P% | V% | Cr% |

| CK45 | .forty two-.fifty | .fifty-.eighty | .04 | .035 | .035 | ||

| ST52 | .22 | 1.sixty | .55 | .035 | .04 | ||

| ST37 | .17 | one.sixty | .fifty five | .04 | .04 | ||

| 20MnV6 | .16-.22 | 1.thirty-1.70 | .ten-.fifty | .035 | .035 | .ten-.twenty | |

| 42CrMo4 | .38-.forty five | .60-.90 | .15-.40 | .03 | .03 | .ninety-1.twenty | |

| 40Cr | .37-.forty five | .50-.eighty | .seventeen-.37 | .08-1.10 |

three.Mechanical Properties

| Material | T.S N/MM² | Y.S N/MM² | E%(MIN) | Problem |

| CK45 | 610 | 355 | fifteen | Normalized |

| CK45 | 800 | 630 | twenty | Q+T |

| ST52 | 500 | 355 | 22 | Normalized |

| 20MnV6 | 750 | 590 | 12 | Normalized |

| 42CrMo4 | 980 | 850 | fourteen | Q+T |

| 40Cr | one thousand | 800 | ten | Q+T |

Organization Data

Consumers close to the globe

Our Solution screen

Trade Displays

Our Providers

Packaging & Delivery

Make contact with us

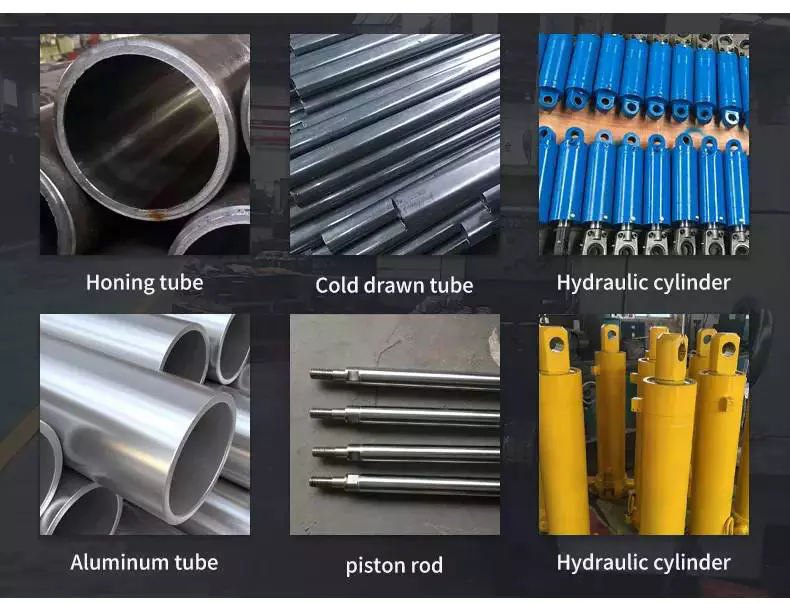

Hydraulic Cylinders and Their Components

Typically, a hydraulic cylinder is used in manufacturing machinery, construction equipment, civil engineering, and elevators. A hydraulic cylinder is also known as a mechanical actuator. A hydraulic cylinder is a type of mechanical actuator that is used to provide unidirectional force.

Piston rod

Choosing the correct rod for hydraulic cylinders can improve the performance and dependability of the machine. While the diameter is always important, the length is also crucial. If the length of the rod is too short, it will crush or fail. On the other hand, if the rod is too long, it will become twisted or misaligned.

The rod seal is the most important seal in a hydraulic cylinder. It protects the cylinder from fluid leaks and system pollutants. It also handles gradual changes in system pressure.

There are many types of seals for hydraulic cylinders. Some of them are special and designed to work under intense pressure. These seals also have backup rings.

A piston rod can be either hollow or solid. It is usually made of steel or stainless steel. It is often coated with hard chrome plating. A polished surface is also an option.

Choosing the correct seal is a crucial step in ensuring the longevity of your piston rod. Rod seals are subject to the most harsh conditions. They need to be made from materials that are slow to wear and will not contaminate the cylinder.

The correct rod seal is also important in preventing fluid leaks. They also protect the cylinder from pressure extremes in the system. If the seal fails, the cylinder will be damaged. The seal is also important because it prevents system pollutants from damaging the rod.

A hydraulic cylinder can be single acting or double acting. Single acting cylinders have one pressurized chamber while double acting cylinders have two. Typically, double acting cylinders have a piston that is extended under hydraulic pressure and retracts under hydraulic pressure.

Piston seals

Choosing the correct hydraulic cylinder piston seal is important to the operation of a hydraulic cylinder. There are various types of seals that can be used to help ensure proper operation of a cylinder. They range from single-action to double-acting seals. The seal’s material and its profile affect its performance.

The materials used to make piston seals range from rubber to thermoplastic polyurethane. The material’s elasticity and strength are also important. Typically, plastic seals have more focus on adding strength to the cylinder than on flexibility.

Rubber seals are used when a higher degree of flexibility is required. They are also used when a higher degree of compressibility is required. Some rubber seals are designed to withstand higher temperatures.

Piston seals are made from a variety of materials, including Viton, nitrile rubber, and polytetrafluoroethylene (PTFE). PTFE piston seals have less friction, which is a good thing. A PTFE seal is also able to handle higher temperatures.

In order to properly seal a cylinder, the seal must maintain contact with the cylinder bore. This ensures that fluid does not flow past the piston. The seal’s profile must also leave a small amount of oil film when it passes along the cylinder bore.

Thermoplastic elastomers are designed to offer superior elasticity. They also stand up to abrasion and high use. They also exhibit unmatched performance at extreme temperatures.

A piston seal can be designed to meet various requirements, including the highest pressures that can be expected. Some manufacturers offer custom sealing solutions. These solutions include testing, according to the customer’s specifications. They can also include failure analysis and system investigations.

Thermoplastic elastomers are also designed to be resistant to tearing. In addition, they are able to maintain a constant pressure for a longer period of time than other materials.

Mounting attachments

Using mounting attachments for hydraulic cylinders can reduce wear and tear on seals and bearings, and provide stability to the cylinder. There are three main groups of mounts: flange, lug, and clevis. Each style is designed for a different purpose. Choose the mount that is best for your hydraulic cylinder.

Flange mounts are a good choice for straight-line force-transfer applications. These mounts come in rectangular or square shapes and can be attached to the head or cap of a cylinder. They are very strong and are not prone to misalignment. They are also available in rod-end styles, which are recommended for tension applications.

Side lug mounts are used for small or light-duty hydraulic cylinders that require a straight-line force transfer. These mounts have lugs on the sides of the mount that are threaded to tie rods. These mounts are primarily used in confined spaces. The lugs can also be pinned on both sides of the mount to prevent movement of the cylinder. The lugs are also strong and can be used in high-pressure environments.

Clevis mounts are also used for arcing loads. They are primarily used on shorter stroke hydraulic cylinders. They can be mounted vertically or horizontally. They are usually used with a knuckle at the rod end of a cylinder. These mounts provide a single pivot point for mounting the cylinder.

Cylinder rod end attachments should be made from spherical bearings to minimize stress on the gland and piston rod. Ideally, they should be positioned as close as possible to the shoulder faces of the trunnion. They should also be threaded to tie rods for a secure connection.

The best mounting style for a hydraulic cylinder is an intermediate fixed-trunnion mount. This type of mount is a good choice for short stroke applications.

Common hydraulic cylinder components

Whether you are looking for a new hydraulic cylinder, or you are considering upgrading the hydraulic cylinders in your current machine, you need to understand the different components of a hydraulic cylinder. Cylinders are used in a variety of applications, including construction, mining, aircraft development, metal sheet shearing, and material handling.

A hydraulic cylinder is composed of two main components. These are the piston and the piston rod. The piston rod protrudes from the cylinder barrel and is attached to the piston inside the cylinder.

A hydraulic cylinder also has seals. These are used to prevent contaminants from entering the cylinder. They are made of many different materials, depending on the application. If the hydraulic cylinder will be operating at a high temperature, it may need a seal made of Viton. In contrast, a hydraulic cylinder operating at freezing temperatures may need a polyurethane seal.

Hydraulic cylinders are also designed to withstand a large amount of force, which means that they need to be able to withstand the pressure of the system. The pressure in the system must never exceed the rated design pressure of the cylinder.

Another important component of a hydraulic cylinder is the cylinder head. It is fitted with a rod gland seal, which encloses the pressure from the other end of the cylinder barrel. A hydraulic cylinder’s head can also be fitted with a check valve, which closes when the stem is clear.

A hydraulic cylinder’s head is also fitted with a rod bearing, which supports the weight of the piston rod. The rod bearing guides the piston rod through the rod gland, and prevents hydraulic oil leakage.

A hydraulic cylinder’s rod can be made from stainless steel or carbon steel. The rod is usually coated with hard chrome plating. The rod can also be made from corrosion-resistant materials, including Inconel.

Common causes of hydraulic cylinder drift

Having a hydraulic cylinder that drifts is not only dangerous, but it can lead to a lot of repair work and costly replacements. Luckily, you can diagnose and fix this problem by performing a few simple tests.

The first step is to ensure that the cylinder is in good working order. It should be checked for general wear, corrosion, and speed. Also, it should be checked for leaks. If there are any leaks, you should fix them right away.

Another way to determine if a cylinder is drifting is to use a pressure gauge. The gauge should be used under controlled conditions to determine if the cylinder is drifting. If the cylinder moves, the problem is likely a leak. You should also check the rod seal.

When the rod seal leaks, it allows fluid to leak outside of the cylinder system. If it does not leak, it should stick to the rod when the rod stops moving. This will prevent a cylinder from drifting and maintain pressure.

The most common cause of hydraulic cylinder drift is a leak. A leak can occur in a number of ways, including through the piston seal or a leak in the holding or pressure release valves. If the leak is in the piston seal, it can lead to a hydraulic cylinder that drifts.

Another common cause of hydraulic cylinder drift is fluid contamination. When foreign particles combine with the fluid, the density can change and oil can seep past seals.

Hydraulic cylinders can experience other issues as well. If the cylinder has an oversized piston diameter, it can cause cylinder drift. A load control valve can also be a problem.

editor by czh 2023-06-27